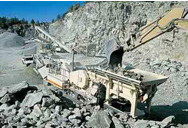

Хятад cone crushing plant

Coviry(Guangdong) Mining and Construction Equipment Co.,

Mobile Cone Crushing Plant, Model CMC300, represents the world advanced high efficient crushers. It is more powerful, higher capacity, intelligent, and wider application.

More

China Cone Crusher Plant, Cone Crusher Plant

China Cone Crusher Plant manufacturers - Select 2024 high quality Cone Crusher Plant products in best price from certified Chinese Mining Machine, Mining Machinery

More

Mobile Crushing Plants-Coviry (Guangdong) Mining and

CMC series mobile cone crushing plant is widely used in secondary and tertiary stages of crushing operations. It has shown excellent stability and performance in crushing

More

Integrated solution provider in fine sandstone

2020.12.7 The process design of the production line is scientific and reasonable, and the whole production process is green and environmentally friendly. Equipment: Jaw crusher + two-stage cone crusher + vertical

More

China Crushing Equipment Manufacturers, Auxiliary Facilities

4 天之前 Hangzhou Cohesion Technology Co.,Ltd: Find professional crushing equipment, auxiliary facilities, stone crushing plant, crusher wear parts, impact crusher

More

China Crusher Plant Manufacturer and Supplier, Factory

Whether you are in need of a primary, secondary, or tertiary crushing system, our Crusher Plant has the capabilities to meet your requirements. Trust in Shanghai SANME Mining

More

China Cone Crush Plant, Cone Crush Plant Manufacturers,

Manufacturer/Factory,Trading Company,Individuals/SOHO,Other,Group Corporation; ISO 9001, ISO 9000, ISO 14001, ISO 14000, ISO 20000, OHSAS/ OHSMS 18001,

More

Jiaozuo Zhongxin Heavy Industrial Machinery Co.,Ltd

6 天之前 Zhongxin Heavy Industry, a modern mining machinery manufacturer, is specialized in researching and developing, manufacturing and selling multi-cylinder

More

Cone crusher,Cone Crusher Manufacturer,Cone

2021.7.14 Cone crusher consist of frame, transmission device, hollow eccentric shaft, bowl-shaped bearing, crushing cone, springs and hydraulic pressure station for adjusting discharge opening. During operation, the

More

Applied Sciences Free Full-Text Prediction of

The pressure on cone crusher liners is the key factor that influences the hydraulic pressure, power draw and liner wear. In order to dynamically analyze and calculate cone crusher performance along with liner wear, a

More

AMIT 135: Lesson 5 Crushing – Mining Mill

The selection of the right crushing equipment is influenced by many factors some of which are upstream of the crushing plant (e.g. blasting pattern and mining method) and others which are downstream of the crushing plant

More

A review of modeling and control strategies for cone crushers

2021.8.15 The minimum distance between the mantle and concave is defined as the closed side setting (CSS) of the cone crusher. The CSS is easily changed online in a large variety of commercial crushers; different principles of CSS adjustment are described in (Quist, 2017).The maximum distance between the mantle and concave, on the other

More

Crushing and Screening Handbook - AusIMM

2021.6.24 Portable crushing plants – excellent trans-portability between sites and fast installation, in addition to high crushing capacities. Can be fi tted with jaw, cone or impact crushers, with or without screens, and equipped with open or closed circuit and discharge conveyors. Mobile screens – track-mounted units for ex-

More

(PDF) ENERGY EFFICIENCY IN COMMINUTION -GETTING MORE FROM THE CRUSHING ...

2020.1.13 The crushing plant performa nce can be further improved b y improving the screening syste m to offer even a finer cr ushed product at d 80 =5–6mm to satisfy the mi lling stage a nd conserve energy.

More

Mobile Crushing Screening - Astec

2024.1.20 Astec offers a broad range of mobile crushing and screening plants, including mobile cone, jaw and impactor plants, as well as a variety of mobile screening and conveying plants. Designed for jobs that require quick and easy site mobility, our mobile product lines give producers flexibility without sacrificing productivity. Engineered to excel ...

More

(PDF) SIZE REDUCTION BY CRUSHING METHODS

2017.3.4 crushers and cone crushers whereas rod m ills and ... semi-mobile and m obile crushing plants with capacities ranging from . 500 to more than 10,000 t/h are used prov ing for crushing and ...

More

Cone Crushers For Sale MyLittleSalesman

2024.1.22 2006 Metso HP400 Portable Cone Plant. Complete work ready plant w/ Switch Gear Starter. 42" Under Conveyor, Hydraulic Legs, Lube Pump System. New Tires, Wheels and Brakes. ... 2022 Powerscreen 1000 Maxtrak Mobile Cone Crushing Plant. Call for price . 16 Hours. Condition: Used: Usage: 16 Hours: Stock Number: EQ0000547:

More

New and used Crushers for sale Ritchie Bros.

About Ritchie Bros. our inventory to find jaw crushers, impact crushers, cone crushers, cone crushing plants, jaw crushing plants, roll crushers, roll crushing plants, and hammermills. More crushers added daily from manufacturers such as Caterpillar, Case, John Deere, Komatsu, JCB, Bobcat and more.

More

Crushers - All crusher types for your reduction needs - Metso

Therefore, clients crushing hard or abrasive materials are advised to install cone crushers for the final crushing and cubicising stage. Cone crushers can in most cases also give a good cubic shape to fine grades. They can be adapted to different applications. This is an important factor, as client-specific needs often change during a crusher ...

More

(PDF) INVESTIGATION OF ROCK AGGREGATE

2021.12.3 The present study investigates the effects of rock crushing circuits on aggregate quality. For this purpose, a crushing-screening plant located in Vize (Kırklareli, Turkey) was considered.

More

Design of a crushing system that improves the crushing

2016.2.10 up. This paper addresses the critical design parameters that will increase the crushing capacity of the plant to 35 tonnes per hour. There are three main steps in designing a good crushing plant: process design, equipment selection, and layout. The paper analyses all of these steps . Keywords . Gold mining, crushing, Zimbabwe, jaw

More

Crusher Aggregate Equipment For Sale MachineryTrader

2023.8.29 Craig, Colorado 81625. Phone: (970) 326-7356. Email Seller Video Chat. Complete Crushing Spread for sale. Call with Questions 1) 1986 1140 Eljay 54” cone plant w/5’ x 16’ screen. SN 42A0386 2) 1974 Cedarapids 22 x 48 jaw plant w/ vibrating feed pan and grizzlie...See More Details. Get Shipping Quotes.

More

Хятад — Википедиа нэвтэрхий толь

2024.1.24 Бүгд Найрамдах Хятад Ард Улс (товчоор Хятад) — Дорнод Азид оршсон бүрэн эрхт улс. Хятад улс 9.6 сая км 2 нутаг дэвсгэртэй дэлхийн 3-р том орон бөгөөд зүүн талаараа Номхон далайд тулж бусад талаараа Вьетнам, Лаос, Бирм ...

More

The pros and cons of cone crusher applications - Quarry

2021.4.16 A cone crusher in a secondary crushing application will typically work with a 3.5:1 to 5:1 reduction ratio. Tertiary cone crusher configurations typically work with a reduction ratio of 2.5:1 to 4:1. The reduction ratio is defined as the ratio of the feed size for which 80 per cent will pass (F80), divided by the product size for which 80 per ...

More

Crushing Plants For Sale MyLittleSalesman

3 天之前 Find Crushing Plants by FABO, Metso, McCloskey, Powerscreen, and more on MyLittleSalesman. ... 2002 Metso HP-300 Single Pass Cone Plant with 36" under crusher conveyor. HP-300 complete rebuild by FEMCO machine shop. Oil lube system and hydraulic adjust system rebuilt, new cooling fan...

More

Ultimate Guide to Cone Crusher Liners: Materials, Designs

2023.2.21 Cone crushers are commonly used in the mining and aggregates industries to reduce the size of raw materials, such as rocks and minerals. These machines are powerful, efficient, and versatile, but they rely on high-quality wear parts to function effectively. In particular, the cone crusher liners, also known as concave and mantle

More

Crusher, Crushing plant - All industrial manufacturers

jaw crusher BR380JG-3. mobile. Capacity: 50 t/h - 240 t/h. Motor power: 159 kW. Opening height: 1,065 mm. Eco-friendly performance moving to a new stage. The operating weight of the BR380JG-3 ranges from 33,500 to 35,310 kg, with a

More

Construction Working and Maintenance of Crushers for

2018.12.26 4 Cone Crushers 20 5 Roll Crushers 23 6 Low Speed Sizers 26 7 Horizontal Shaft Impactors 29 8 Ring Granulators 42 9 Rotary Breakers 48 10 Manganese Steel 49 11 Lubrication 50 ... Efficiency of a multiple stage crushing plant can be maximized by operating a primary crusher at a setting which produces a satisfactory feed size for

More

The improved model of inter-particle breakage considering

2017.10.1 The cone crushers (ZS200MF) are utilized for the fine crushing in this mineral process. The test object of ZS200MF in the production is hematite, gneiss and granite. The crushing performance of ZS200MF is simulated by using the improved model considering the transformation of particle shape. Base on. Discussion

More

A review of modeling and control strategies for cone

2021.8.11 production goals of aggregate plants are substantially different from these of a crushing circuit in a mining plant (Rylander and Axelsson, 2013). The profit of a quarrying plant is heavily impacted by the product properties (flakiness, shape, strength, and bulk density) (Ruuskanen, 2006). 2.3. The usage of cone crushers

More

YUNNAN KREAT HEAVY INDUSTRY SCIENCE ...

KREAT cone crushing plant can match different crushing cavity types according to customers’ different demands, that it has brilliant features such as high productivity, fine aggregate sizes, low cost on abrasive parts in any kind of use.

More

(PDF) Cone Crusher Performance - ResearchGate

2015.5.13 Applied to Cone Crushing”, Minerals Engineering, V ol. 10, 199-214, February. 1997. ... Crushing plants have very different layouts depending on when and for what purpose they.

More

MODELLING, SIMULATION AND OPTIMISATION OF A

2017.8.23 back to the same crusher for further crushing Comminution Generic name referring to any minerals processing operation used to achieve size reduction of minerals and ores Crushing plant An arrangement of equipment which reduces or changes the size of large rocks into a specified smaller size Crushing Ratio Ratio between in-coming feed

More

Types of Rock Crushers Quarry Crushing Equipment Kemper

2 天之前 Typically, the minimum setting on most primary crushers will be about 4 to 6 inches, as noted above. Compression-style jaw, cone, impact crushers, and gyratory crushers are most often appropriate as primary crushing equipment types, though there can be overlap between primary and secondary crushers as far as suitable types. 2.

More

(PDF) Automated process control system of Jaw crusher

2021.12.1 The analysis of the characteristics of the technological equipment and individual aggregates of the mobile crushing and screening plant is performed.A software for automated cone crusher control ...

More

6 Granite Crushers for Efficient Granite Rock Crushing

2023.5.12 The six best-selling granite crusher machines are jaw crusher, cone crusher, impact crusher, sand making machine, mobile crusher, and portable crusher. This article will share with you the pros and cons of these granite crusher machines to help you pick the right one. The reason for the popularity of granite rock crushing equipment is the

More

Cone Crusher Liners: How to Select and When to Change

2020.6.23 90-100% passing the closed-side feed opening. Some people look at 80% of the open side as well and select the smaller of the two. 40-60% passing the midpoint. 0-10% passing the closed-side setting. A well-graded feed to the Cone Crusher. You want to match the entire feed gradation, not just the feed size, so that you utilize the entire chamber.

More